Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() May 31, 2022

May 31, 2022

If you want to cut the material, there are many ways to achieve it, such as using sawing and gas cutting, etc..All can achieve the cutting of various materials.

But these cutting methods are not perfect, so water jet cutting and laser cutting were invented later, which are also widely used now. It turns out that these two methods are also the most effective cutting solutions in the industry.

But people have not stopped looking for better cutting methods, such as the processing of some precision metal parts, or the cutting of some new materials, which need to find new cutting methods.Thena unique water jet laser cutting technology is developed.

First, let's take a look at the differences and similarities between the two cutting methods, water jet and laser cutting.

First: Definition

Water jet, which uses water as a knife, pressurizes the water in the container to ultra-high pressure, and then shoots high-pressure water through a very small nozzle, so as to realize the cutting of materials; in order to increase the cutting ability, some pomegranate sand, Abrasives such as diamond are added to water. It is now a widely used cutting methods.

The abnormal processing method, combining water jet and laser cutting, this idea is amazing.

Laser cutting is to create a high-power laser beam through a machine, and then irradiate it to the material to be cut. The high temperature generated by the laser will melt or vaporize the irradiated material, thereby realizing the cutting of the material.

Second: cutting material

Water jet has almost no limit on the material that can be cut. Water jet cutting will not allow the material to generate heat, thus avoiding the melting, warping, bending, burning and other phenomena of the material being cut; common types of materials for water jet cutting including plastic, rubber, stone, ceramic tile, stainless steel, and other metals.

Laser cutting is capable of cutting a wider range of metals, including stainless and carbon steel, as well as aluminum and many other alloys. Some kinds of laser can be used to cut through non-conductive materials such as wood, glass, or plastic, but the heat generated by the laser can be harmful to some kinds of metals.

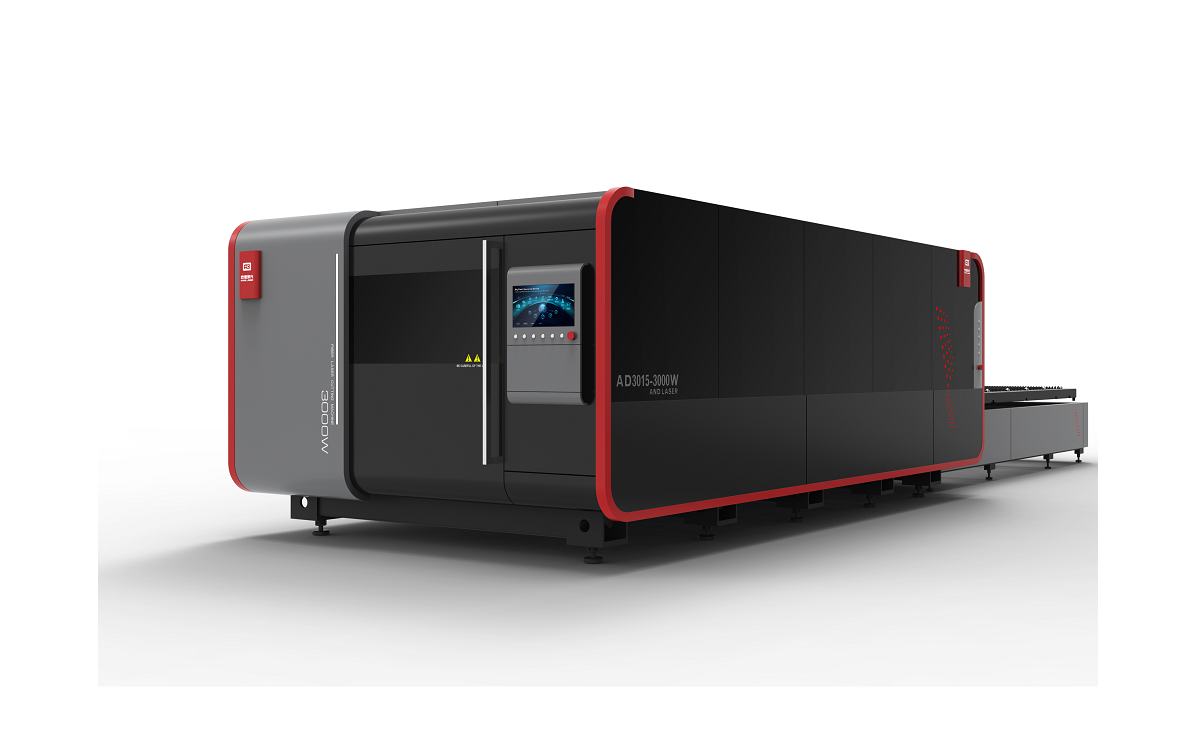

Laser cutting manufacturer Ande Laser Intelligent Equipment (Guangdong) Co., Ltd. is a laser equipment manufacturer integrating R&D, production and sales, mainly engaged in laser cutting machines, laser pipe cutting machines, laser welding machines, laser marking machines and other series Equipment, if you have any questions about laser cutting machines, please feel free to consult.

Part of the content of this article is organized from the network sharing, if there is any infringement, please contact the editor to delete it.

The above is the Combining water jet and laser cutting, the idea is amazing! we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.